HyTech Racing is Georgia Tech’s Formula SAE Electric Vehicle team. We have a simple mission that drives all the hard work the team puts in: build the next generation of engineers through the pursuit of vehicle performance.

In 2023, I was the President of the team, leading over two hundred members. We had to struggle for every positive outcome and stay focused during the near-disaster moments. Engineering was made more difficult by drastic financial setbacks, the bureaucracy of our school, and supply chain delays. However, we enjoyed solving the never-ending list of technical problems. In that entire year, something went wrong till the very last day of our competition, but I was never bored!

Results

- 1st Place Accelration : North American Accelaration record broken

- 1s Place Skidpad

- 1st Place Autocross

- Business Presentation Finalists

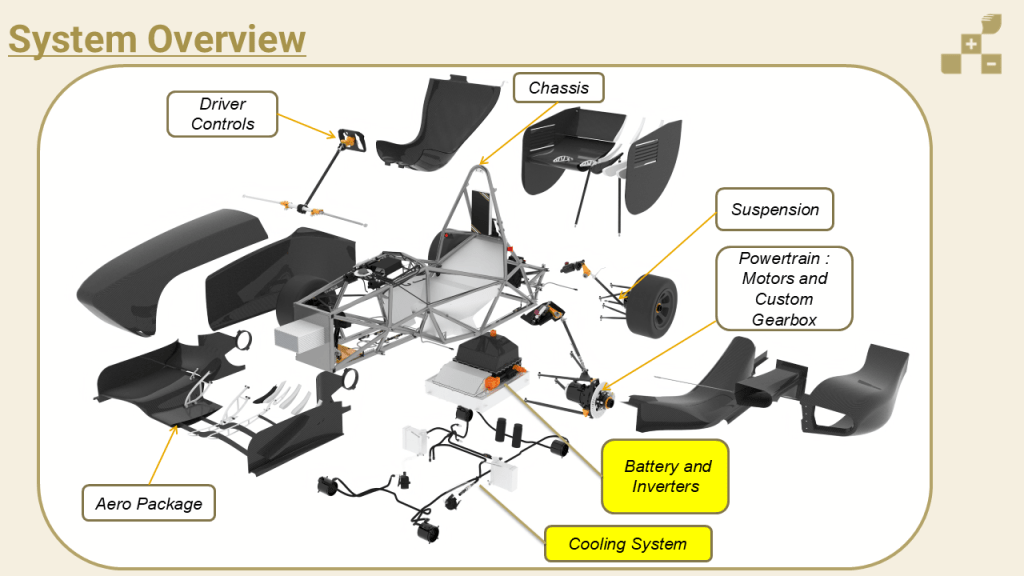

System Overview and Battery Architecture

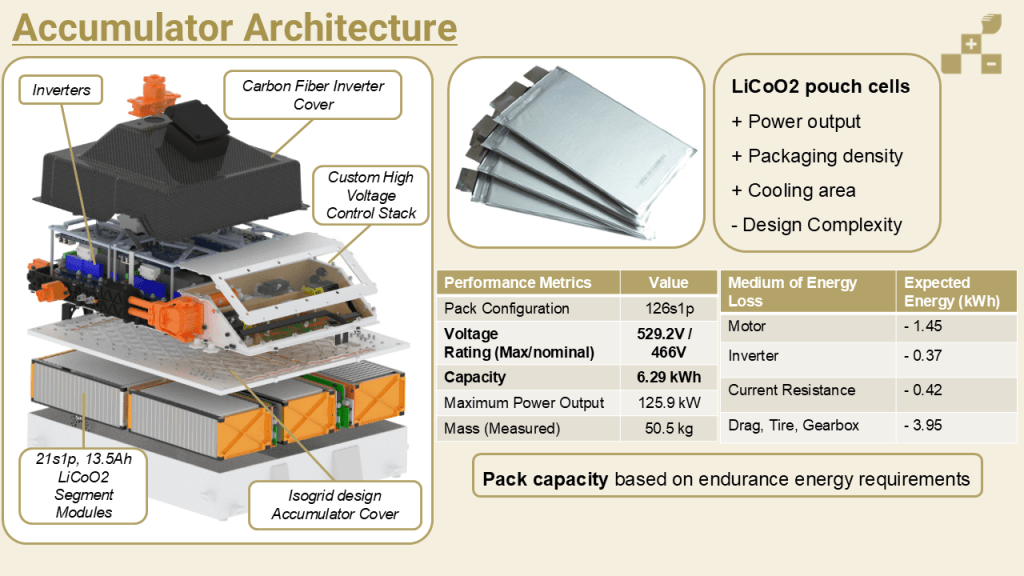

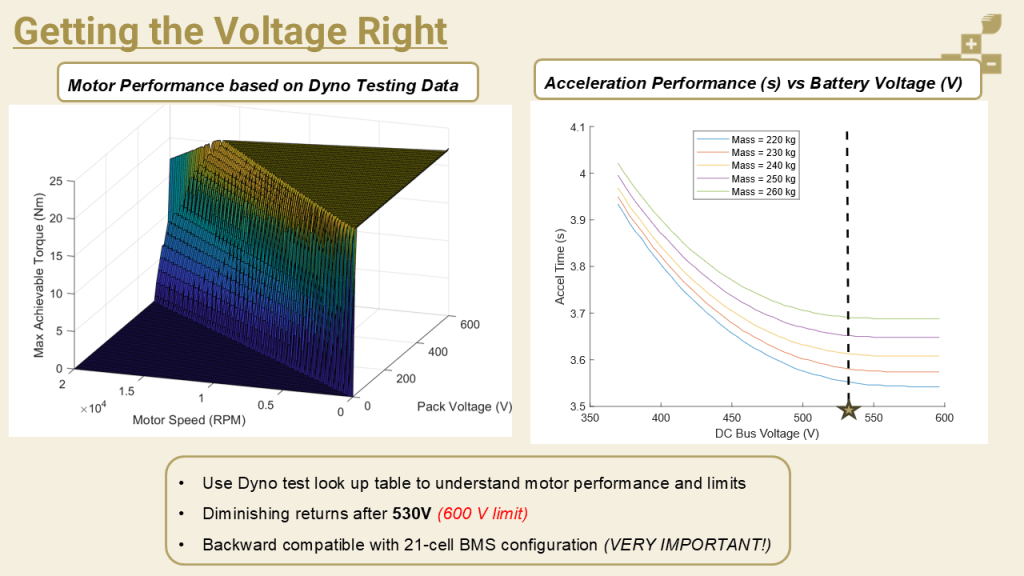

The goal of the Electric Drives sub team was to design a light battery pack with optimum voltage for acceleration performance and just enough capacity to finish endurance. These slides show the overall process of selecting our architecture and the design of some key sub-assemblies.

Tools used and Lessons Learned:

- Engineering is a game of tradeoffs

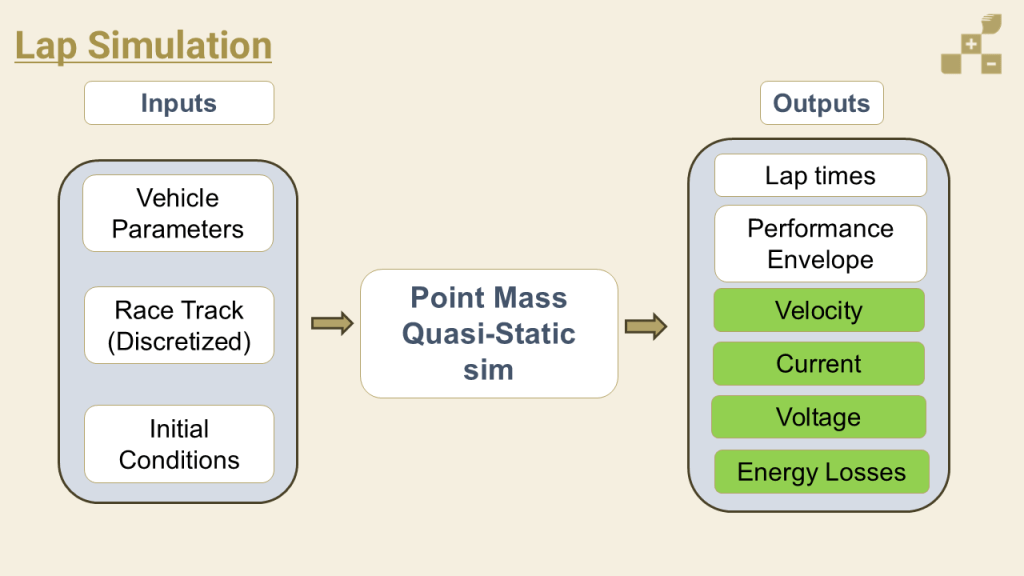

- Simulations can almost predict the future : )

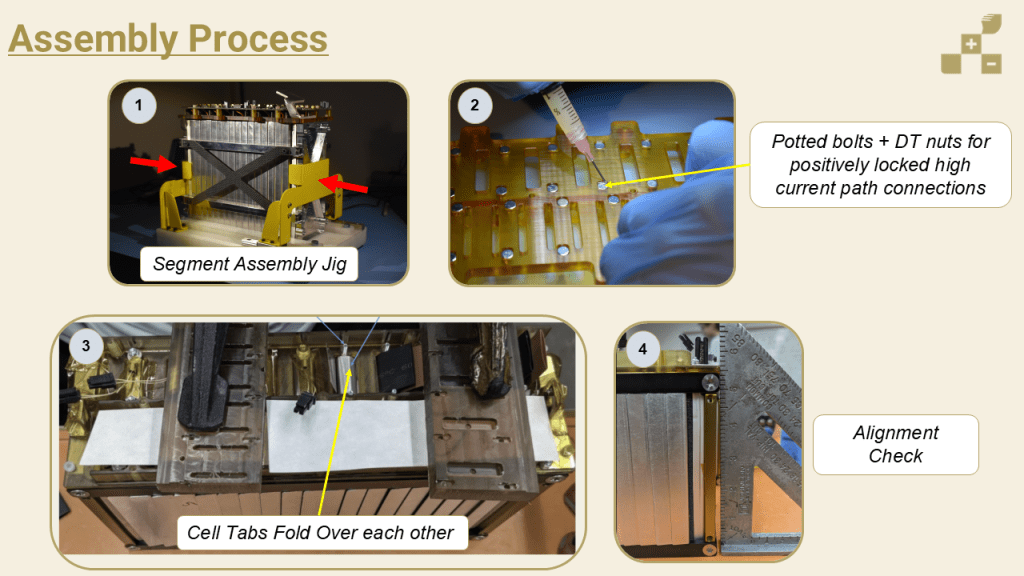

- High Voltage Assembly : 126 cells — Vehicle Integration

- Make sure each part in the assembly plays a role.

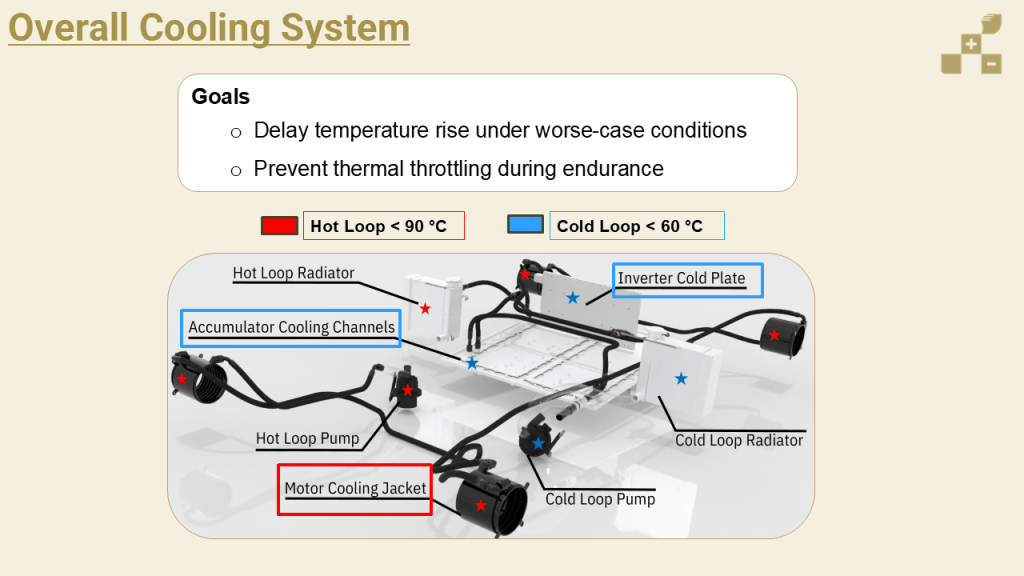

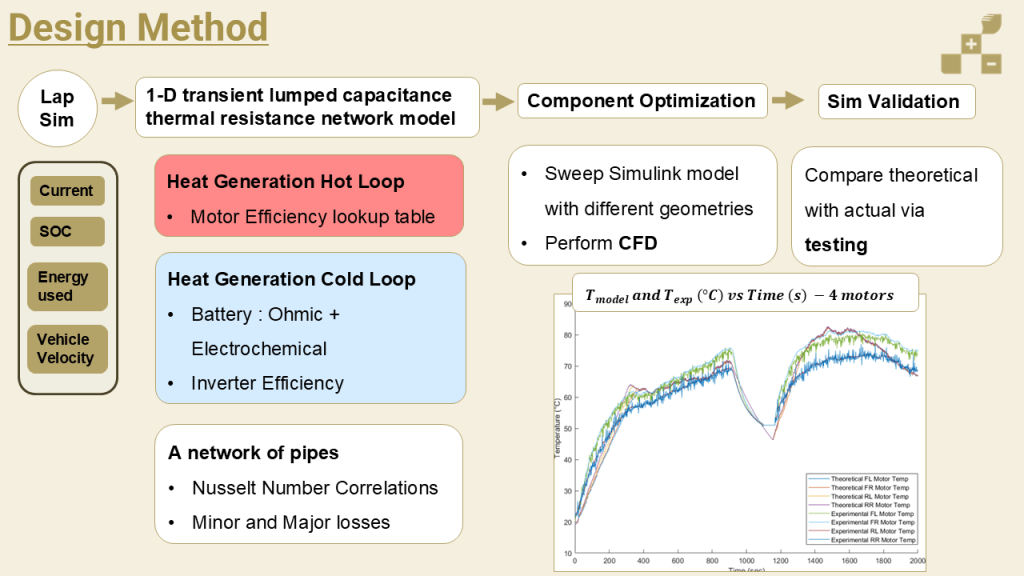

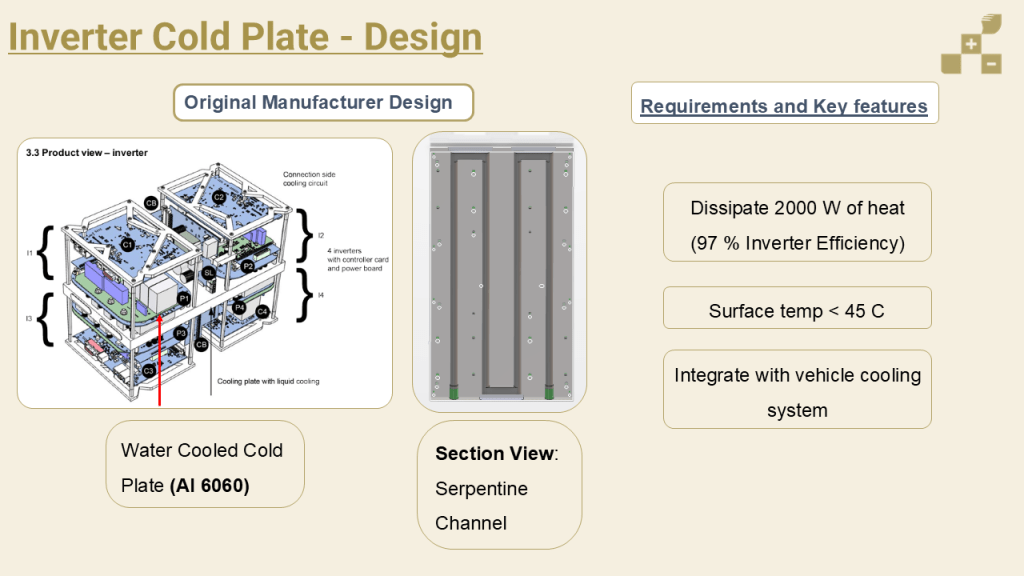

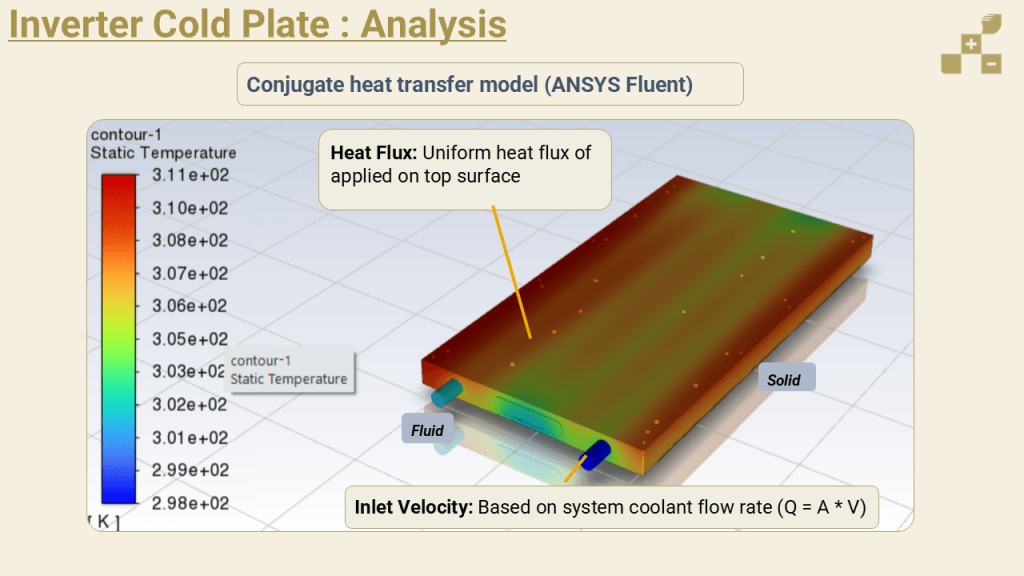

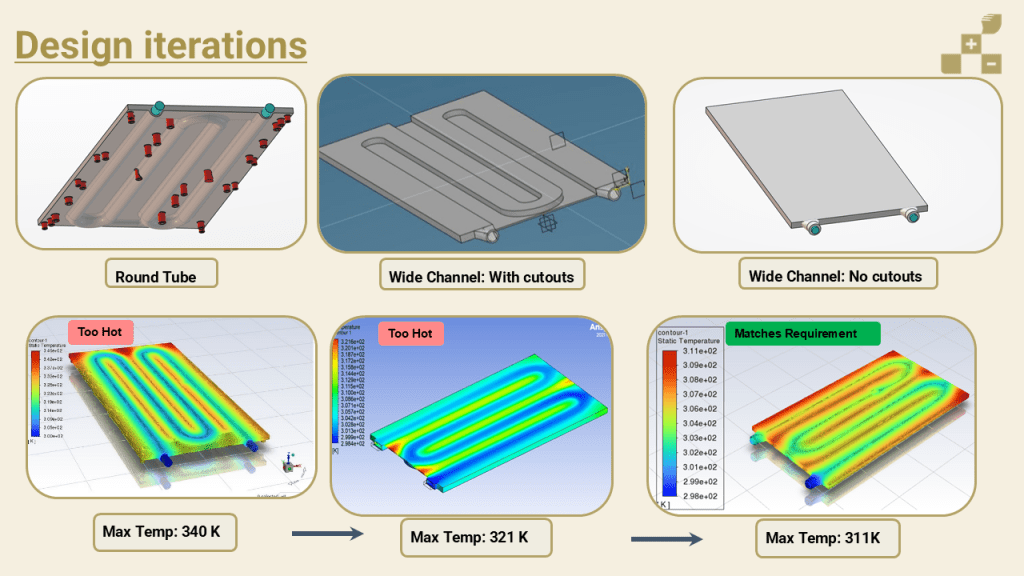

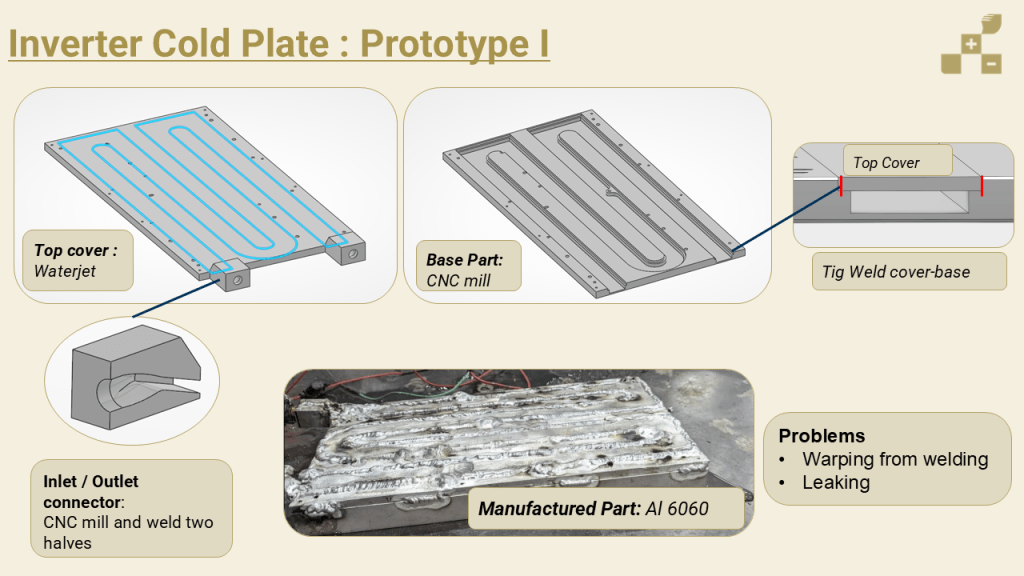

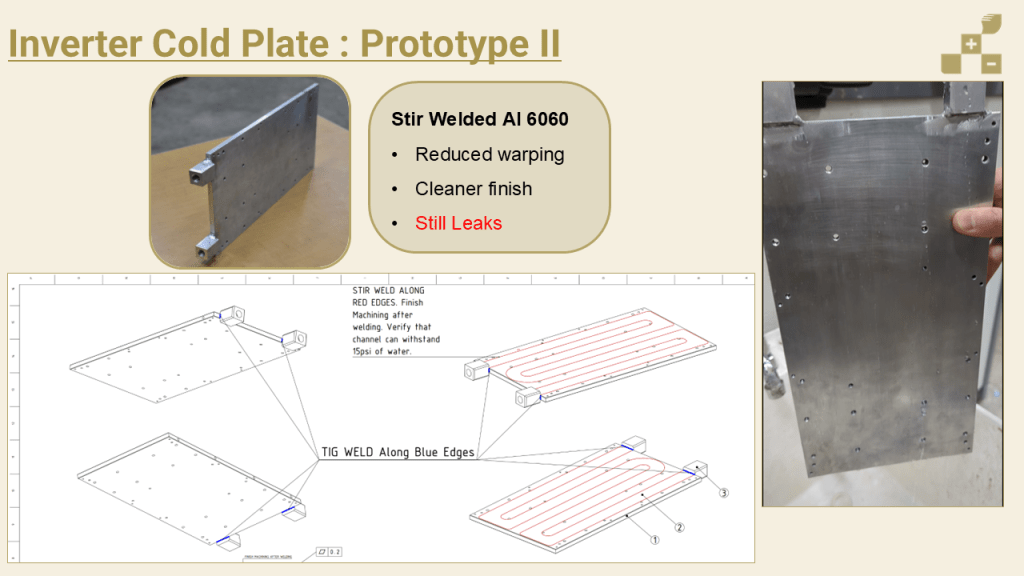

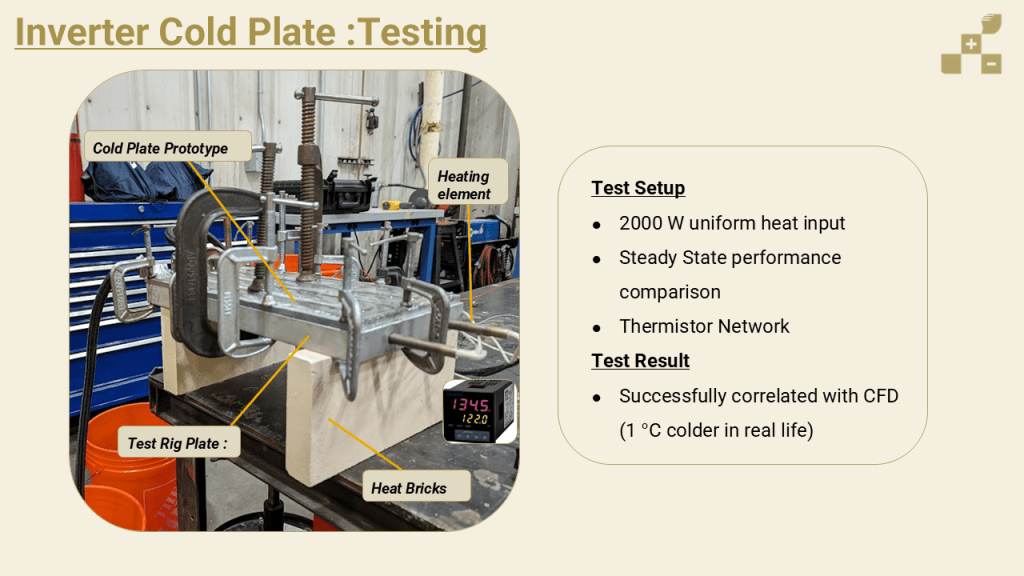

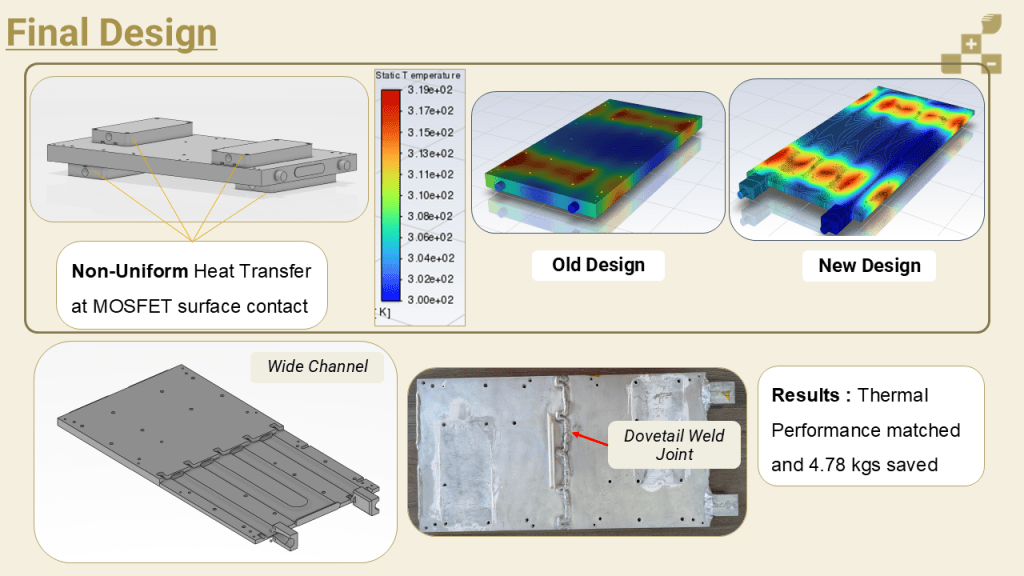

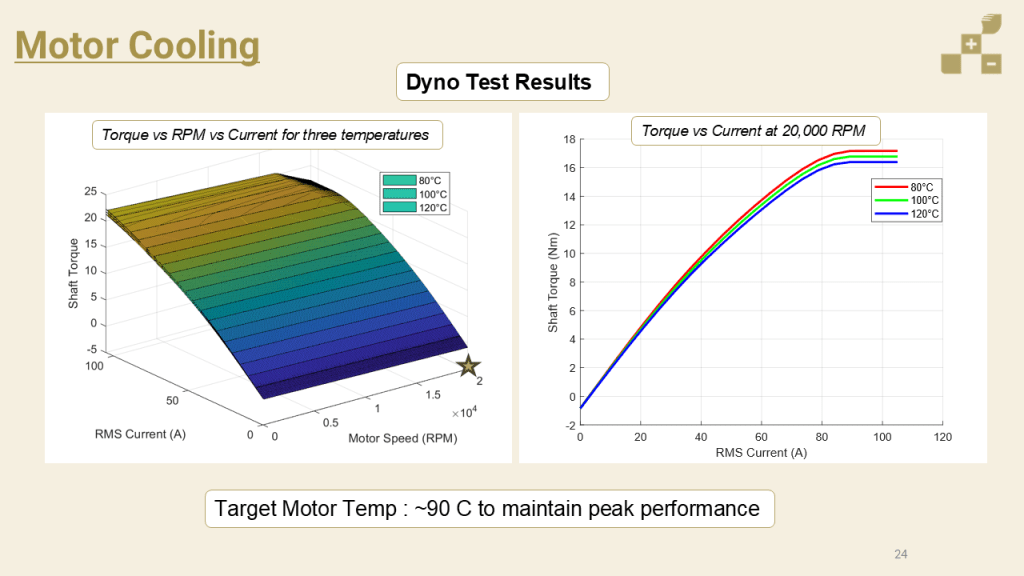

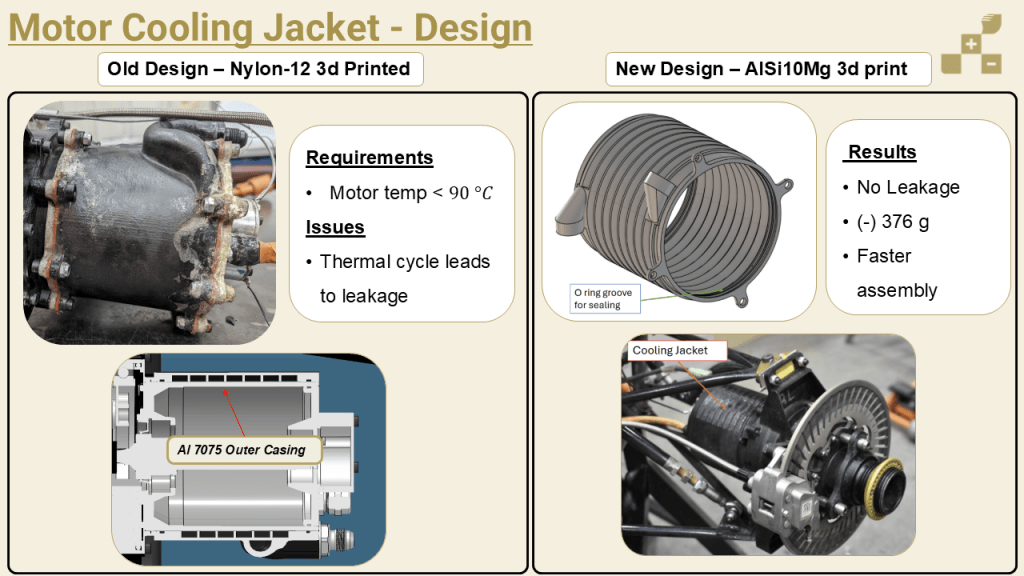

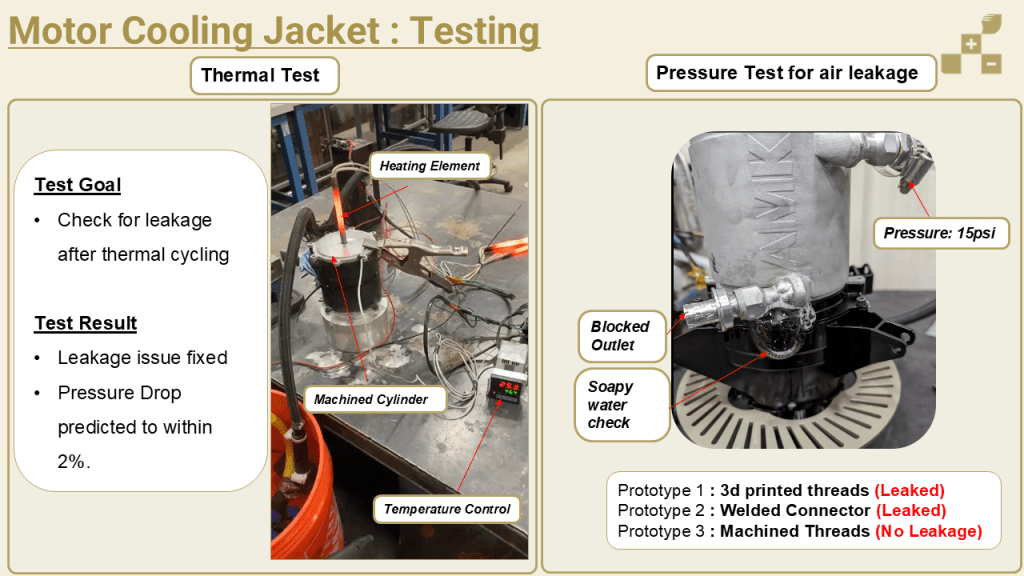

Thermal System Design

The process of going from the electrochemistry of the battery to the peak 1.2g straight-line acceleration a driver experiences has inefficiencies! The goal of our cooling system is to ensure the heat generated by these inefficiencies is dissipated and critical components like the battery, inverters, and motors are always at safe and optimum temperatures during endurance. These slides illustrate the overall system-level view down to component-level testing and the simulations used to build our cooling system.

Tools used and Lessons Learned:

- Colors For Dollars on Ansys Fluent

- Resistance Network Models in Simulink

- Testing Setup to validate thermal simulations

- When in doubt of simulation, use experimental data

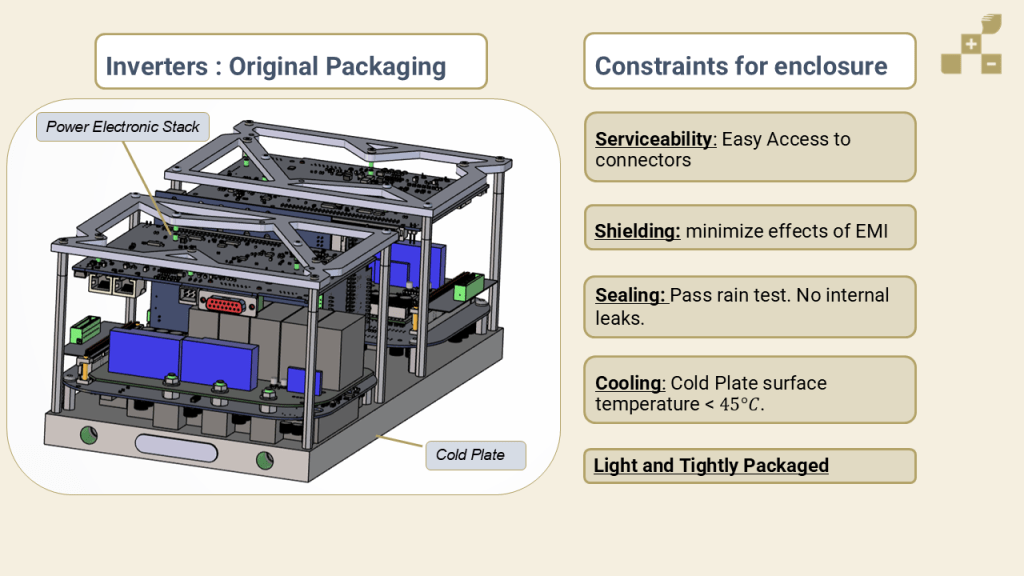

Inverter Packaging

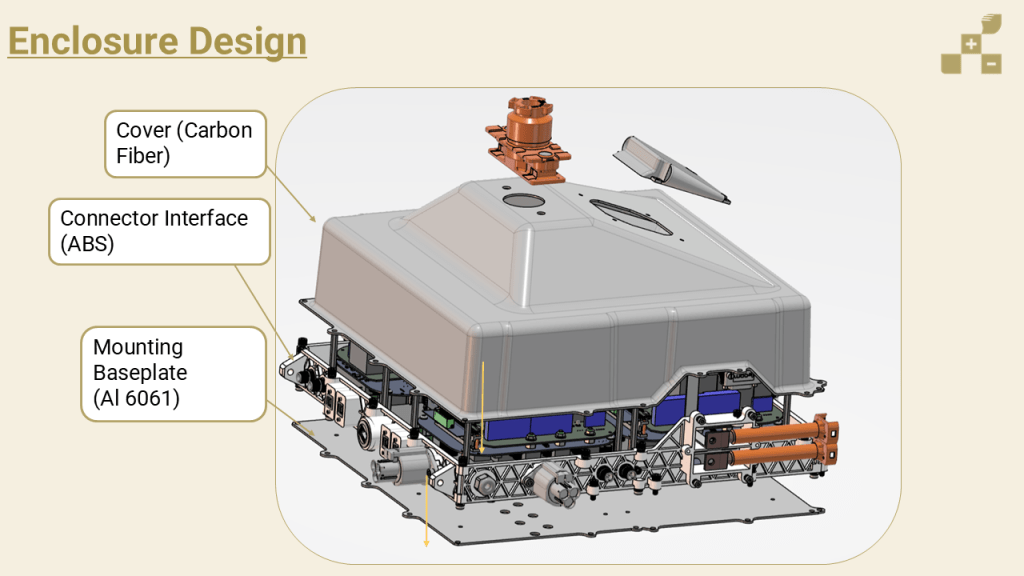

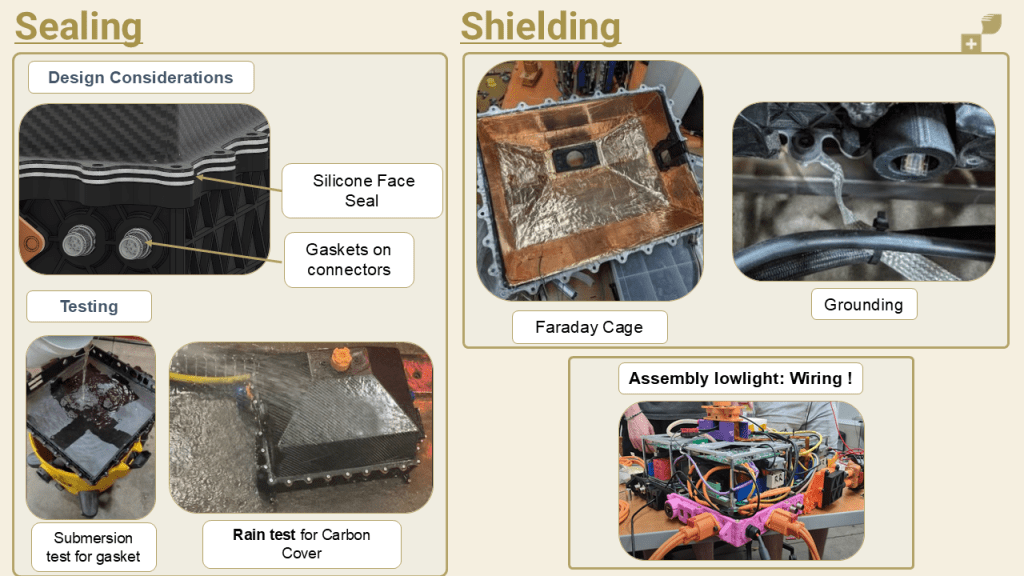

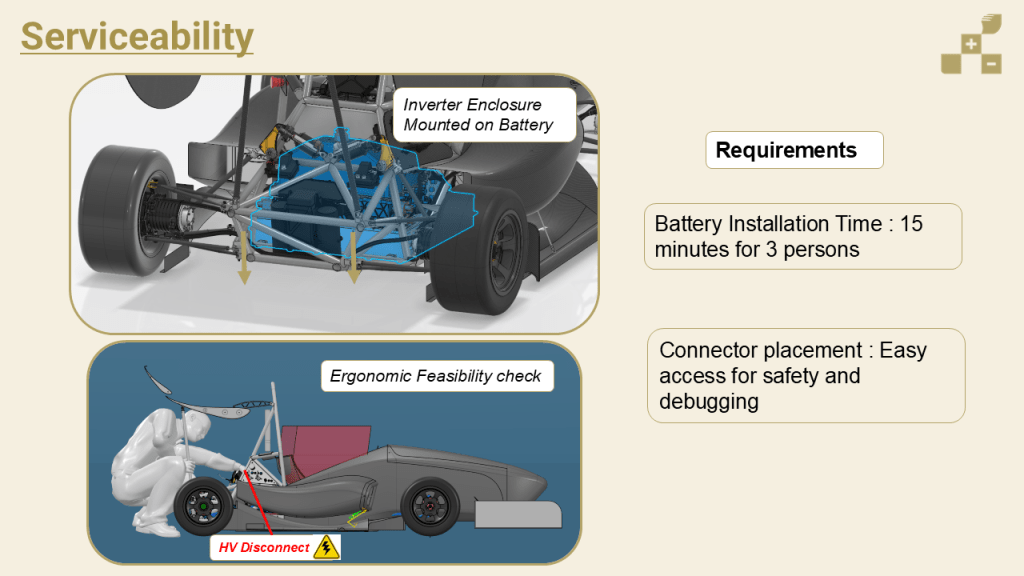

Our original inverters came with no packaging, these slides explain the enclosure I designed and assembled.

Tools used and Lessons Learned:

- Organized, top-down, skeleton based CAD on Catia V6

- Electronics Packaging: EMI reduction, Wire harnessing

- Waterproofing electronics: real life testing > simulations

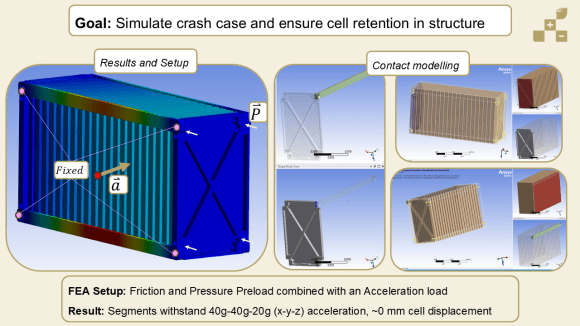

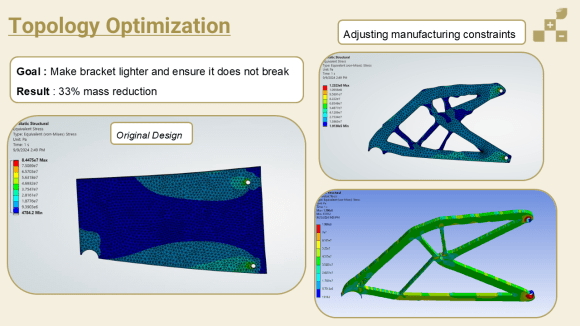

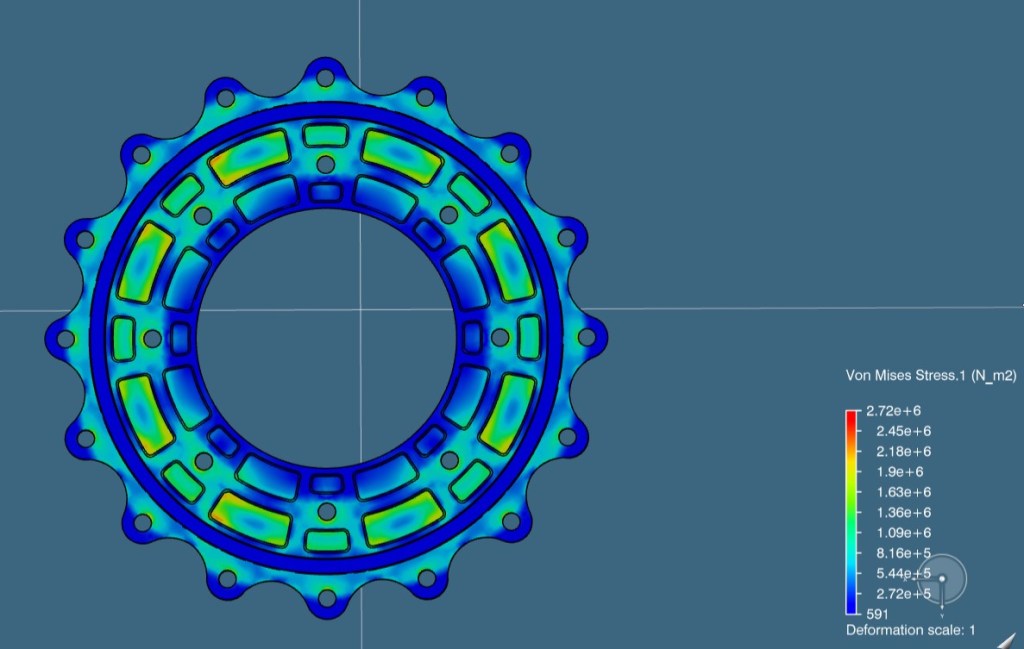

Structural Analysis

A lot of work goes into making sure that a racecar does not break when it moves. The slides below show some of the FEAs I ran to validate and optimize different components and assemblies of the vehicle. The most challenging simulation I worked on was on our battery segments to make sure that the cells did not fly off during a crash.

Tools used and Lessons Learned:

- ANSYS Structural, Topology Optimizations, and contact based modelling

- Understanding the physics is the hard part, clicking buttons on a fancy software is tedious but easy

Older Projects

After taking 3rd place in the 2022 competition in Michigan, our focus this year was improving our design based on data and simulations. The results from our lap simulation showed improved lap times with hub motors. This required significant changes to the powertrain and accumulator architecture as we transitioned to hub motors.

Accumulator Overview:

| Pack Configuration | 126s1p |

| Voltage Rating (max) | 530V |

| Capacity | 7.1 kWh |

| Cell | 13.5Ah LiCo2 (6 segments 21 cells each) |

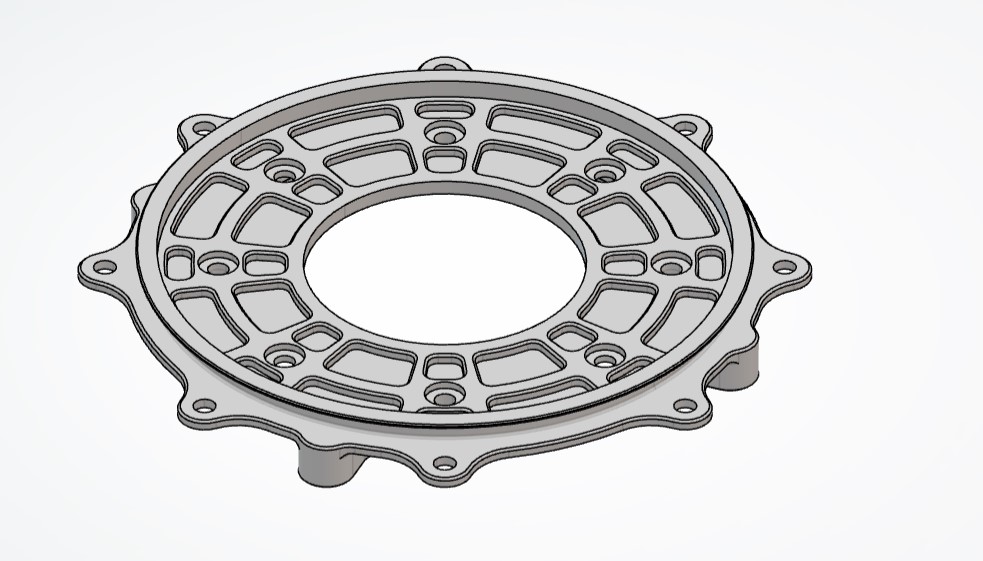

Motor Mounting Plate

Another Project that I worked on was designing the motor mounting plate for the powertrain sub team. The plate is required for assembling the powertrain of the car, and it connects the motor to the upright (structure that connects the a-arms to the Tyre while housing the gears of the powertrain).

Figure: Final Design of the Motor Mounting Plate

After designing the initial structure, which accounted for both connections, I performed FEA to validate the design and optimize the weight of the part by removing material in an organized way.

Figure: FEA results on motor mount plate

An important limitation of my FEA was that I applied the boundary conditions and loads to an isolated part. This resulted in the model predicting a very high safety factor because it discounted the bolt pre tension load and the interface between other parts in the assembly. Under high suspension loads the deflections of the upright have a considerable effect on the motor mount plate.

Another requirement for this plate was sealing with both the interfaces (upright and motor) since the gearbox would be in an oil bath. To prevent leakage O-rings were used for sealing. This needed a well designed sealing interface based on the o-ring and the mating part.

Figure: Powertrain Assembly: Upright (purple) designed by the suspension team, motor (grey), Motor Mounting Plate (black) interfacing with both parts

Adding proper tolerances to the part was essential since plate would be used to center the motor. This required the central hole to have the same nominal diameter as the motor shaft to give a locational clearance fit. Additional considerations such as fillet size and location were also made in order to successfully machine the part on the CNC mill while avoiding unnecessary operations.

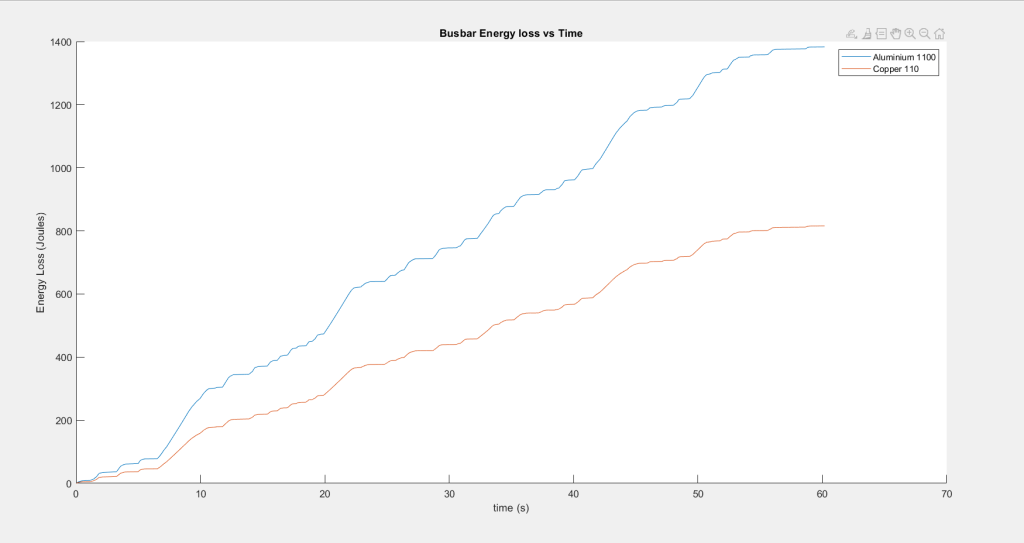

Busbar Analysis

The purpose of this study was to estimate the energy loss due to busbar resistance in the high voltage circuit of an electric vehicle. I used Matlab to evaluate two different materials Aluminum 1100 and Copper 110.

| Aluminum 1100 | 110 Copper | |

| Energy Loss (kwh) | 0.0085 | 0.0050 |

| Loss relative to Battery Pack | 0.11% | 0.07% |

| Mass | 117g | 387g |

Copper outperforms Aluminum due to having lower resistivity but the following tradeoffs exist:

- 270g of mass added to the car.

- Copper is less manufacturable than aluminum and it is more expensive. Since the bus bars will be manufactured by our team these factors are important.

The study validated our material choice of using Aluminum, but it highlighted the loss in accumulator capacity (although relatively small) which could be factored in for future battery designs.

Competition Results :

2021-2022

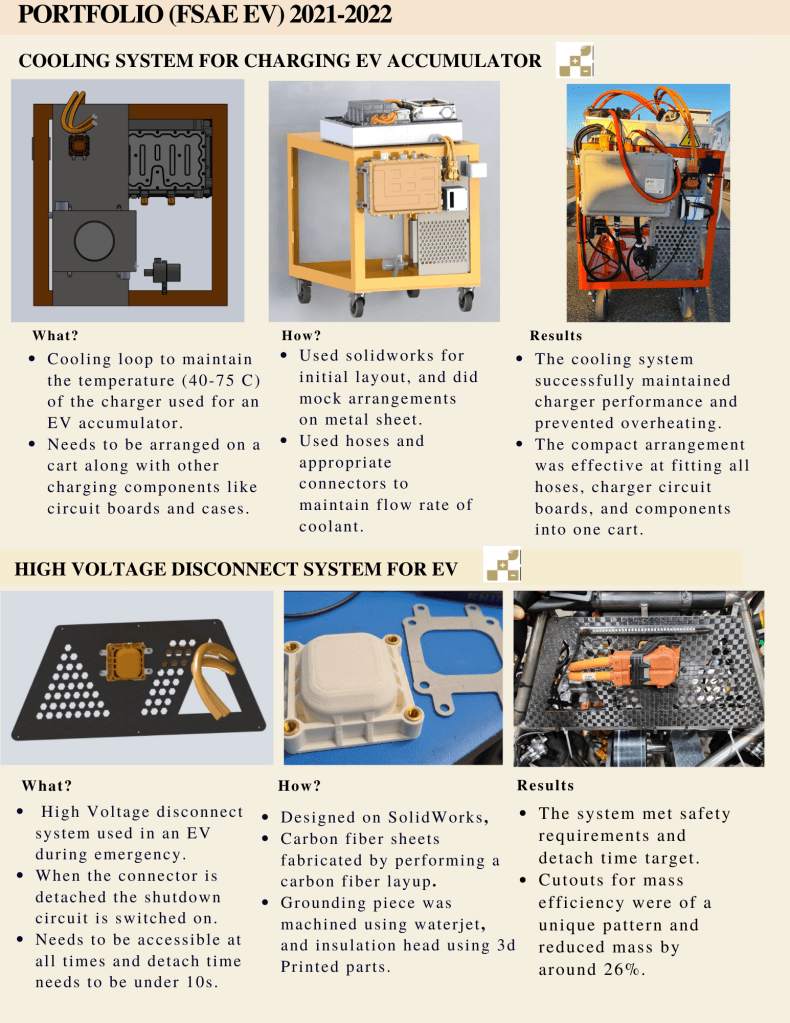

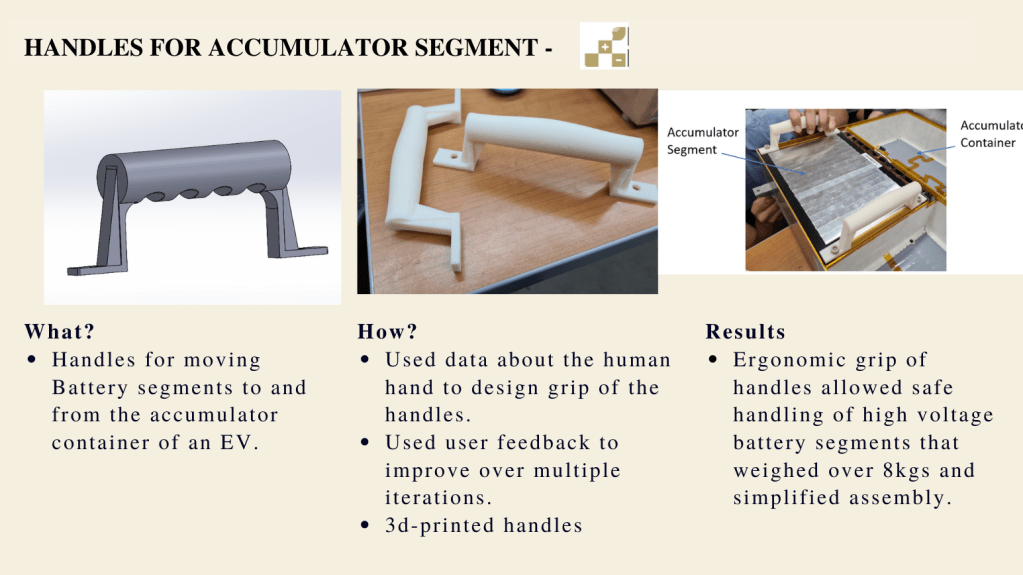

This is the beginning ! I started with no engineering experience and learned how to design and build basic assemblies. The following are some of the projects that I worked on in my first year.