Walking into a car factory is quite an experience. Honking cars carry components across the factory. Workers rush to get to their shifts. Giant Robots seem to magically assemble complex pieces together. As I walk to my desk on the first day of work, two words cross my head “Controlled Chaos”…

In the summer of 2023, I had the opportunity to intern for Rivian as a Process Engineering Intern and below is the most special project I got to work on.

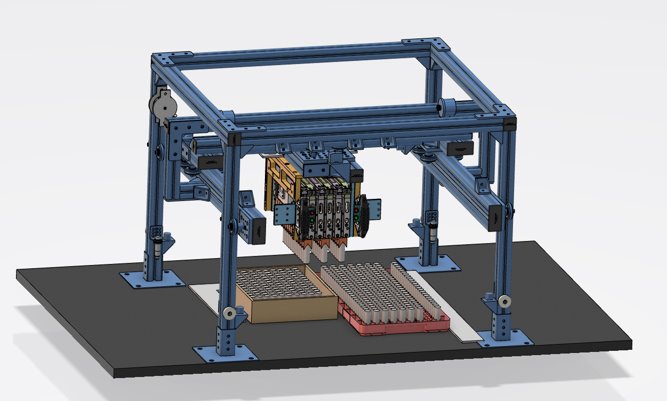

Cell Transfer Device

What?

An ergonomic device that helps speed up the currently laborious and tedious process of transferring battery cells between boxes. The device executes the following steps:

- Pick up cells from box 1.

- Change the intercell distance in x and y to match box 2 dimensions

- Release the cells to the correct position in box 2.

- Reset the intercell distance in x and y to match box 1 dimensions.

- Repeat step 1.

The ultimate goal of deploying this work station was to improve worker productivity and reduce the head count.

How?

There is a certain intimidation I feel whenever I am starting from a blank canvas. Designing this device from scratch on CATIA took a lot of long days, critical thinking, and a fresh perspective every day.

I started the process by understanding the user of this device. I performed a two-hour shift where I replicated the manual process of transferring cells between boxes. Six cells were all I managed to fit in my small hands, and doing this for eight hours a day was unimaginable! This experience of playing the role of the final customer was critical in designing a satisfactory experience for the operators of this device.

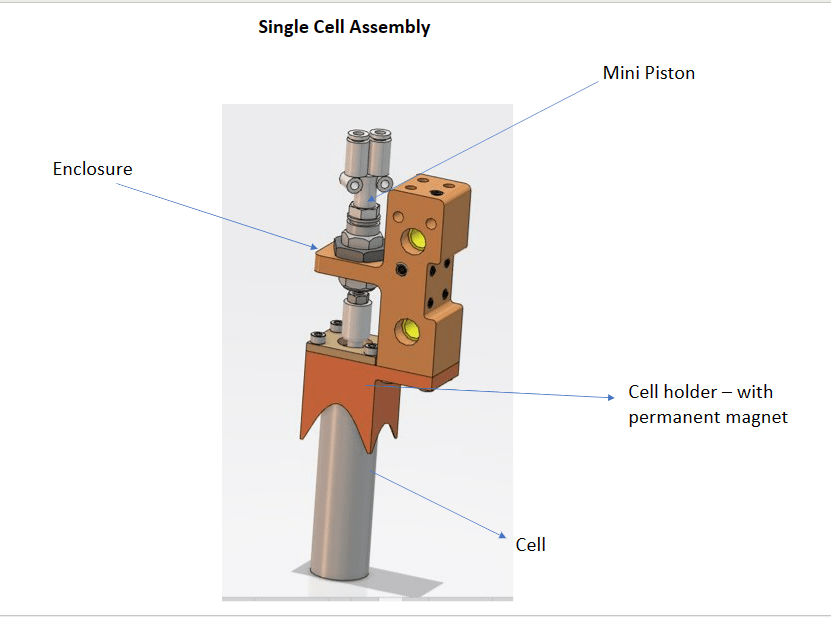

The building block of the entire assembly is the cell holder. It uses a permanent magnet that the cells stick to when it comes into position. The mini pneumatic piston is used to gently tap the cells so they fall down. The structure that houses these components is split into two separate pieces machined from Delrin. This modular design makes it easy to service damaged cell holders.

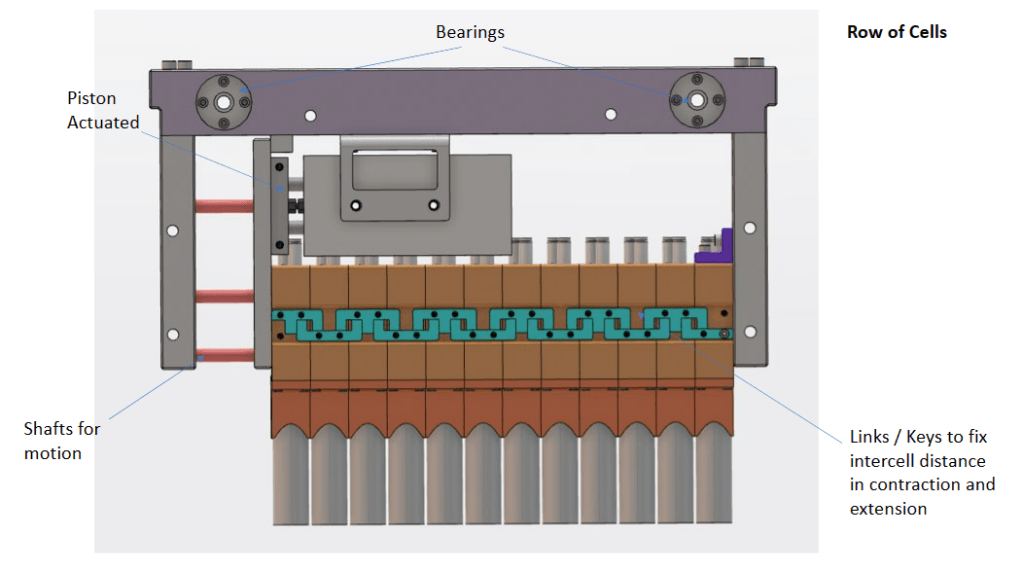

12 of these cell holders are mounted on a Row. In order to change the intercell distance a piston is used to extend the entire row along with carefully positioned hard stops and links. The entire row frame and the links will be made from Aluminum 6061 and be machined using a CNC mill.

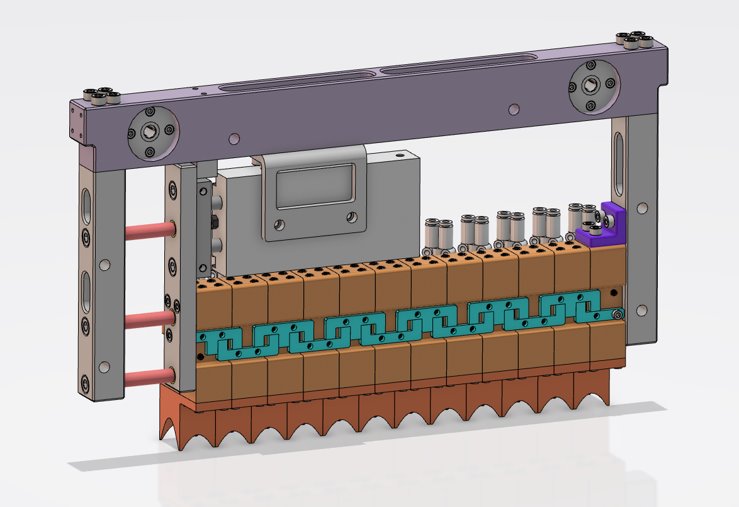

3 of these rows are assembled along with a PLC controller and a valve manifold to complete the end of arm tool.

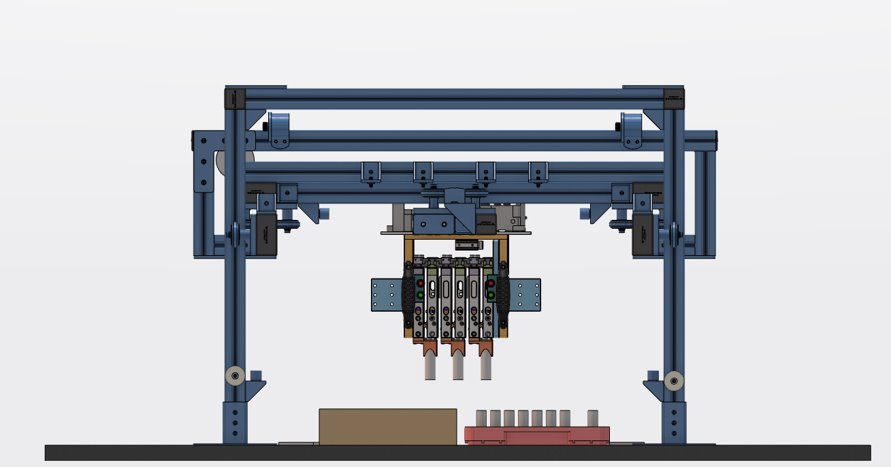

The end of arm tool is then mounted to a 3D cartesian gantry (also designed from the ground up) to aid motion. Multiple ergonomic considerations such as inter handle distance, maximum extended length, load of the device was done to make sure that workers do not get fatigued while using the device.

To say that this was intense would be an understatement! My internship ended on a Friday. At 6 am on Thursday I still needed to finish all the drawings and the BOM to be sent out to manufacturers. Those last 48 hours at Rivian were some of the most memorable moments of my first internship!

Results

A 400% improvement in cycle time sounds like a lot, but manually hand stuffing cells is not that hard to beat. This improvement was derived from a cost analysis based on the theoretical speed of this device. The analysis revealed that adding just one of these devices would match the current output and reduce net costs by 89%.

Room For Improvement

Like all Projects, in retrospect there are multiple things I would have done better. I did not have time to validate my designs through testing of different assemblies, and this was critical in ensuring that this station would work. Making mistakes due to initial flawed assumptions was another extremely time-consuming problem.

One of these significant mistakes that I did not catch early enough was the use of electromagnets in the design. At first, I naively thought I had come across a significant improvement by implementing electromagnets for picking up and dropping the cells. They enabled smaller packaging, improved wiring and were easy to control.

Just as I was about to order one of the electromagnets for testing, I saw an Amazon review that highlighted that electromagnets would get hot. Then the classic joule heating formula Q = I^2R popped up and that dominated the destruction of this idea.

These small electromagnets would be switching on and off thousands of times a day, and without a cooling system this would be a thermal hazard and reduce performance. This was a very simple mistake to catch, and despite being skeptical I could not figure it out until I had completed a large portion of the design around electromagnets! Having a more organized process of asking the right questions early on would have saved me a lot of time.

Going from zero to one is always really difficult, but it is a very rewarding process. Every day it felt as if there was another project ending problem, but with multiple iterations and careful thinking I managed to solve most of them. I am certain that some issues will reveal themselves when the device is assembled, which I could not think of while designing, but that is the name of the game!